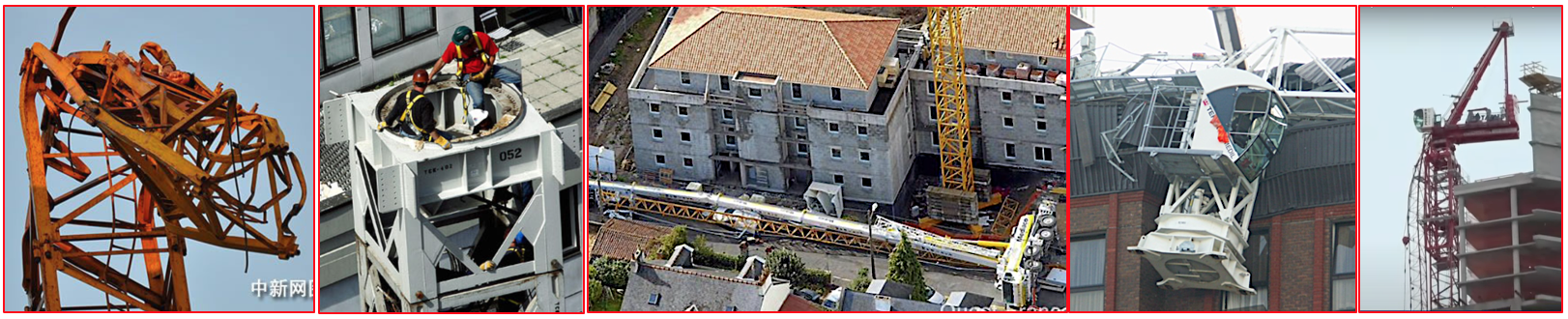

USA, 08 - Crawler crane got in path of tower crane. Jib had to be removed due to damage.

3-13-10 USA, Tower crane jib collapse due to high wind.

Reported wind was only 65mph -"weathervane" ?

2010 Zimbabwe - Truck crashes into tower crane - takes out support. 2010 Singapore - Dismantle / Climb collapse. 3/26/10 Russia - Structural / foundation failure - Operator dead. 2010 Germany - Self erect falls into another, safety limit failure. 2010 Accidents. 2010 - Canary Islands, another WIND accident 2010, Italy 2010, Austria - Operator was last seen walking to back of crane - fell to his death

2008, Spain - Erection accident

Close calls and lessons NEVER learned:

On their third section - - their luck "almost" ran out! PAGE - 1 -2 -3 -4 -5 -6 -7 -8 -9 -10 -11 -12 -13 -14 -15

VIDEO

VIDEO

VIDEO VIDEO

VIDEO VIDEO

You would think with all the past lessons learned, along with the growing personal liability being levied all the

way up to the "top of the food chain", those in the tower crane industry would be on the straight and narrow - but

this is not the case. In the tower crane world, "common practices" (currently lobbied as employer procedures)

are regularly used when it comes to climbing, which are not based on an engineered analysis, but solely on the

premise that it work without consequences in the past.

Case in point:

A Peiner - SK575 tower crane was to be climbed down for dismantle. The TSK climber support beam already

had one missing bolt from the climb up, but that was of no concern the last climb or this climb - - too niether

the crane vendors technician nor the climbing crew. So, as it often goes, the climb commenced regardless

of imperfect conditions.

picture for illustration only

Continuing on, they gambled on another common practice which is to NOT re-install and tighten all mast bolts

before putting the crane in an unbalanced condition - - which happens when the balance section is sent to the

ground in order to retrieve the just extracted section from the tray. Increasing the stakes even more - - when

re-connecting the tower section back to the TSK, yet another common practice of leaving the nuts way loose

was also employed.

Due to the combination of the enormous reverse back moment when a tower crane has no load on it, along

with not properly reconnecting the tower section back to the TSK section, i.e. not following manufacturer

instructions. Moments after the balance section was disconnected on the ground - - the stress on the climber

beam bolts was too great - and two of the left front climber beam bolts sheared off, jolting the crane backwards

- - almost loosing the entire top structure!

This not only over-stressed the remaining bolts on the TSK climber support beam, but quite possible the climber

structure itself. The proper procedure after such an incident would have been to stop climbing operations,

replace all bolts, and conduct a thorough examination of the climber structure.

With "only" one more tower section to be climbed out, and with now "only" three missing bolts (out of 8) on

Oh the Humanity!

This is not a rare event; ignorance like this goes on more often than you are aware of, and by the hands of well

known (so called) experts. The company involved in this incident is highly regarded in the industry and even active

on crane safety committees. A warning to all that are passively standing by allowing pub-engineered procedures.

You better hope I'm not contacted by the NEXT deceased plaintiff's lawyers!

16 -17 -18 -19 - 20 -21 -

22 -

23 - 24

HOME